ZK series CNC deep hole drilling machines factory

Product Description

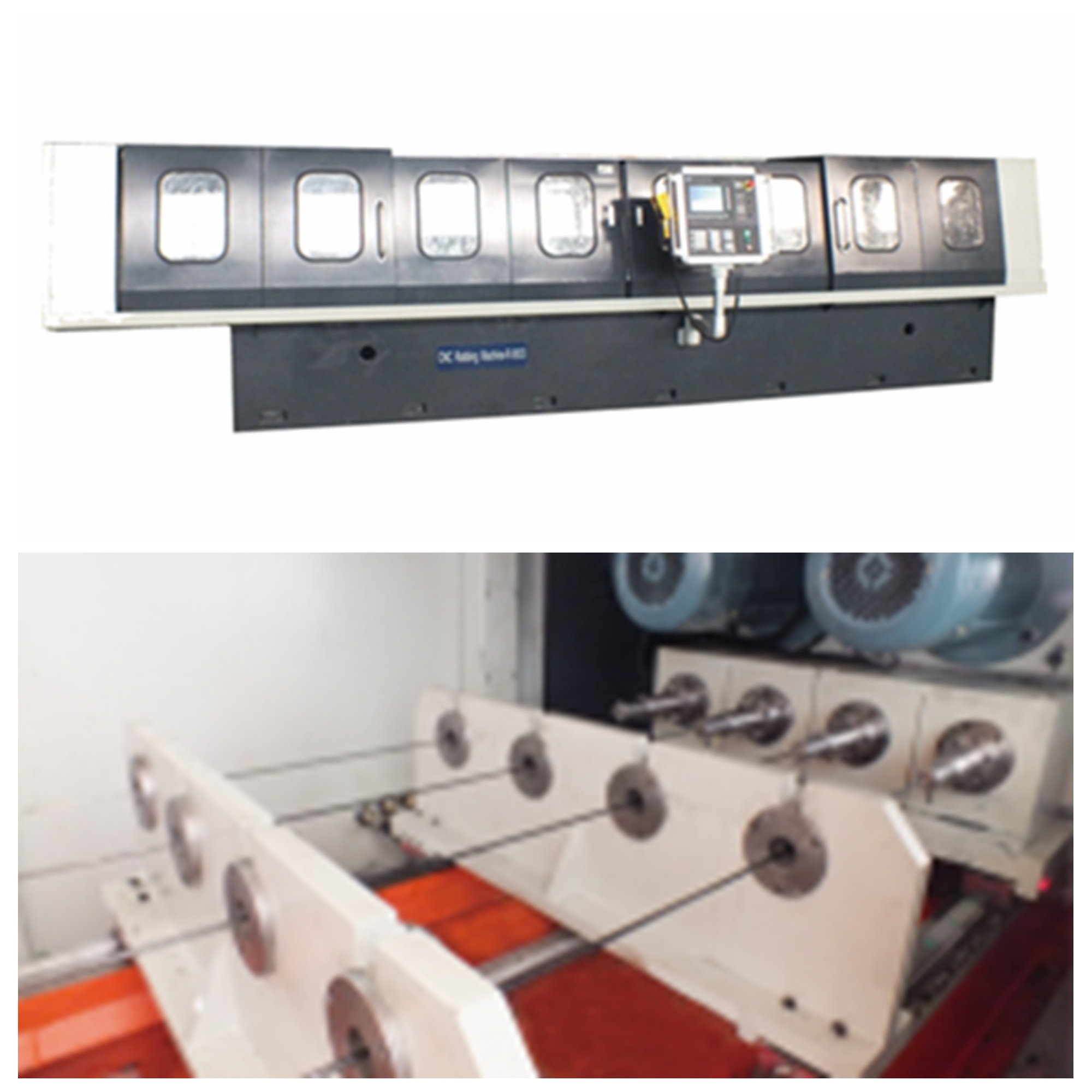

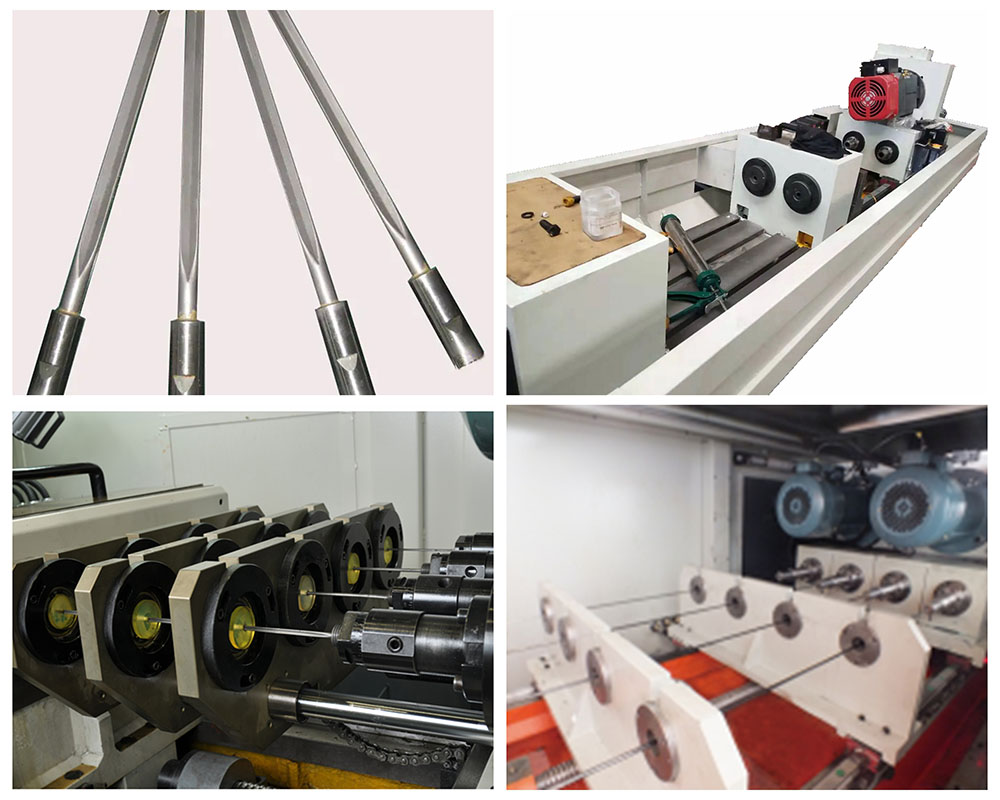

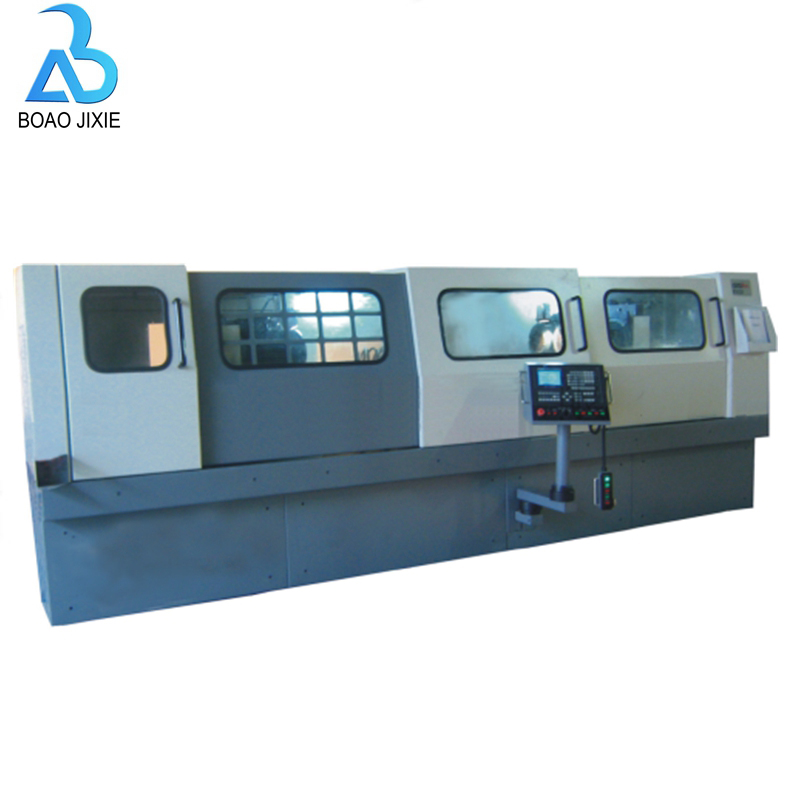

Our company is a professional manufacturer of deep hole equipment in China. Designed the ZK series deep hole drilling machine for the market. There are several models of this deep hole drilling machine with a certain number of spindle drills, which makes the application of the machine tool more extensive. We can use this machine tool for small-quantity production maintenance work, as well as for mass production and manufacturing industries.

ZK series machine tool is a special deep hole drilling machine with high efficiency, high precision and high automation. The external chip removal drilling method (gun drilling method) can replace the machining accuracy and surface roughness that generally require drilling, expanding and reaming processes to achieve through one continuous drilling.

This machine tool is controlled by a digital control system, not only has a single action function, it also has an automatic cycle function. In order to improve processing efficiency, this model is also equipped with 2 and 4 power head structures. Therefore, this machine tool is not only suitable for small batch processing, but also suitable for the processing requirements of mass production. It can drill through holes as well as blind or stepped holes. Eccentric holes and oblique oil holes can also be processed with special tooling.

Specifications

|

NO |

Items |

Description |

||

|

1 |

Machine model series |

ZK2102A |

ZK2102A-2 |

ZK2102A-4 |

|

2 |

Spindle quantity |

1 |

2 |

4 |

|

3 |

Spindle distance |

/ |

120mm, 180mm |

120mm |

|

4 |

Drilling diameter rang |

Φ3-20mm |

Φ3-20mm |

Φ3-20mm |

|

5 |

Max processing depth |

500mm/1000mm |

500mm/1000mm |

500mm/1000mm |

|

6 |

Headstock spindle speed |

380 r/min or no headstock |

600 r/min or no headstock |

500 r/min or no headstock |

|

7 |

Drill box spindle speed |

800-7000 r/min |

800-7000 r/min |

800-7000 r/min |

|

8 |

Feeding speed range |

5-500mm/min |

5-500mm/min |

5-500mm/min |

|

9 |

Coolant system pressure range |

1-10 Mpa |

1-10 Mpa |

1-10 Mpa |

|

10 |

Coolant system flow |

6-100L/min |

6-100L/min |

6-200L/min |

|

11 |

Feeding carriage rapid speed |

3m/min |

3m/min |

3m/min |

|

12 |

Feed motor torque |

7Nm |

7Nm |

11Nm |

|

13 |

Feeding carriage rapid motor power |

4KW |

4KW*2 |

4KW*2 |

|

14 |

Headstock spindle motor power |

1.5KW |

3 KW |

2.2KW*2 |

|

15 |

Machine total power |

20KW |

24KW |

40KW |

|

16 |

Control system |

Siemens or KND |

Siemens or KND |

Siemens or KND |

|

17 |

Power supply |

380V, 50HZ, 3phase |

380V, 50HZ, 3phase |

|

Photos Wall