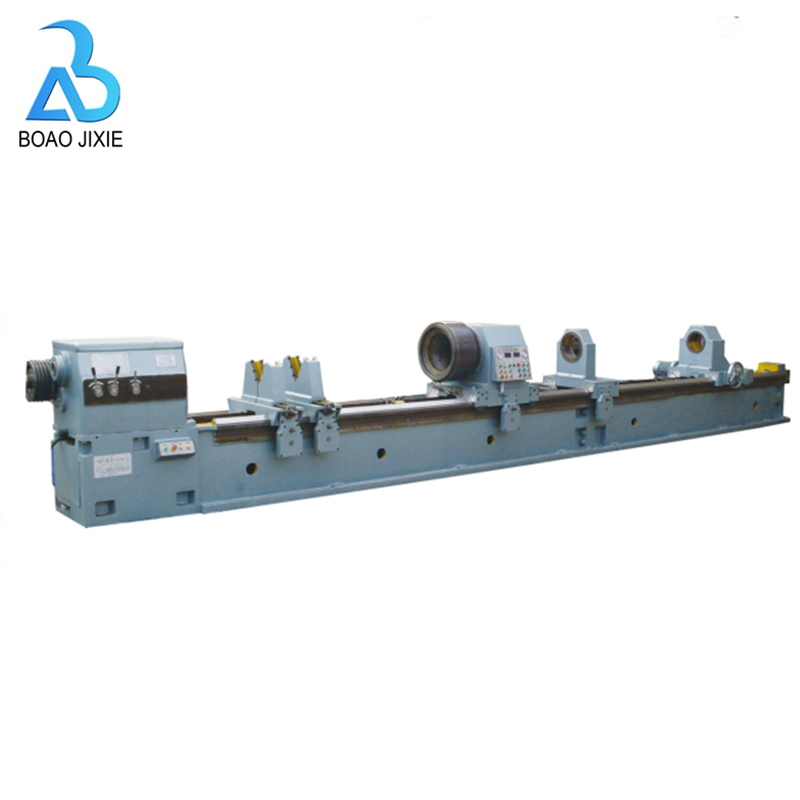

T2280H type deep hole boring lathe turning machine

Machine Character

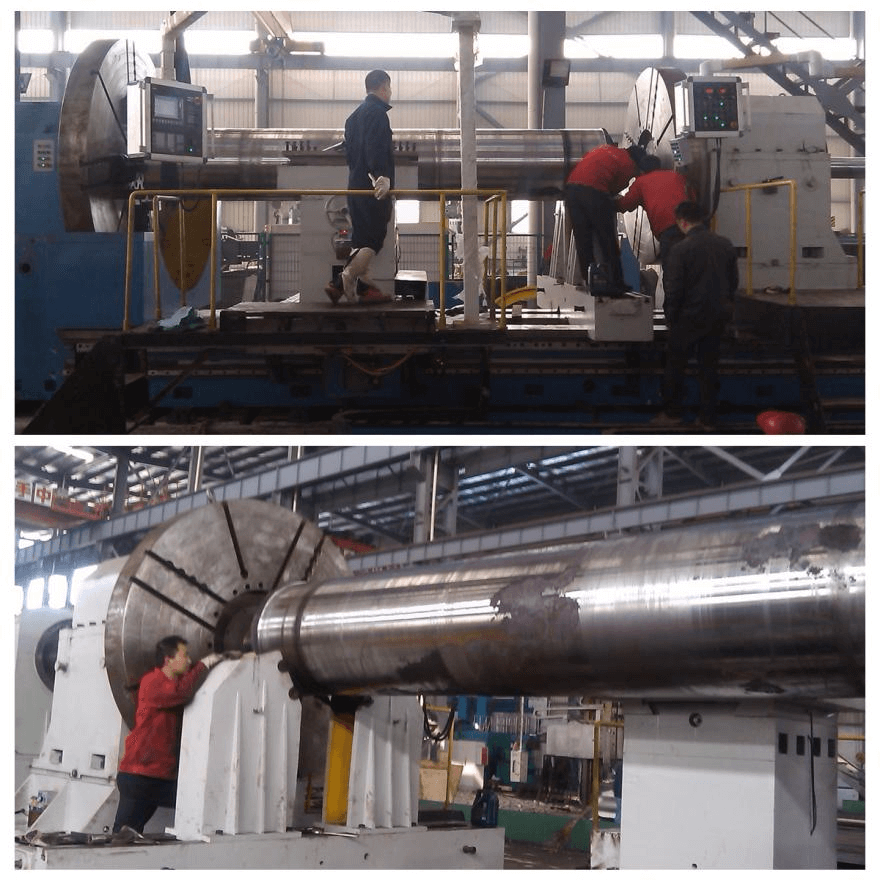

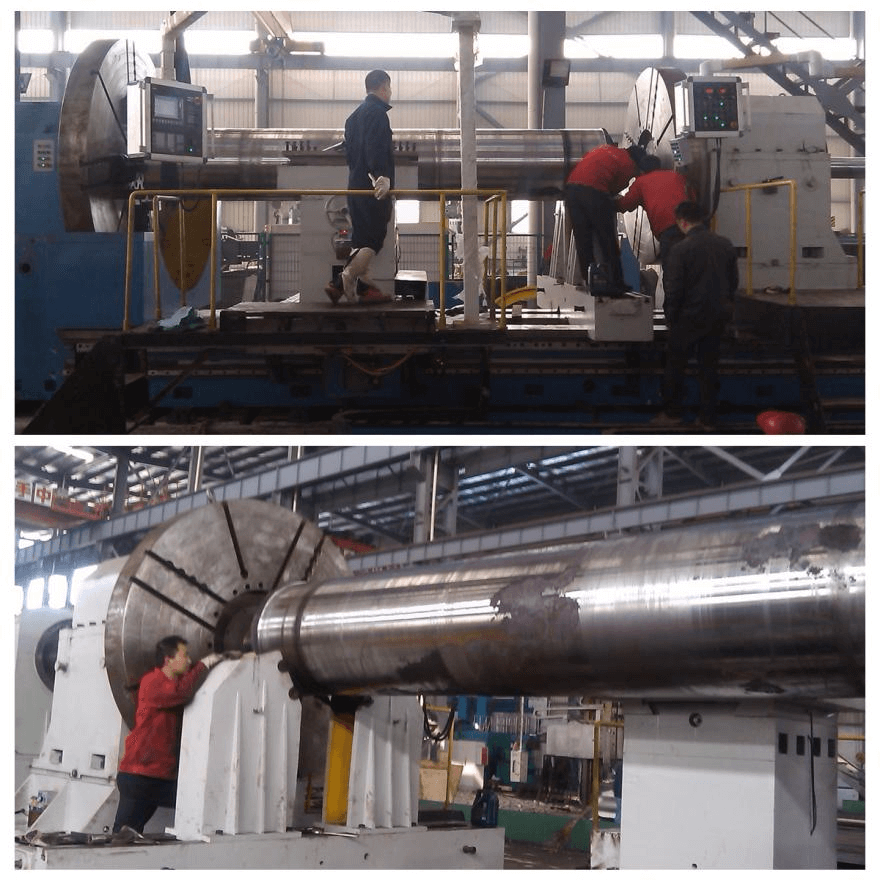

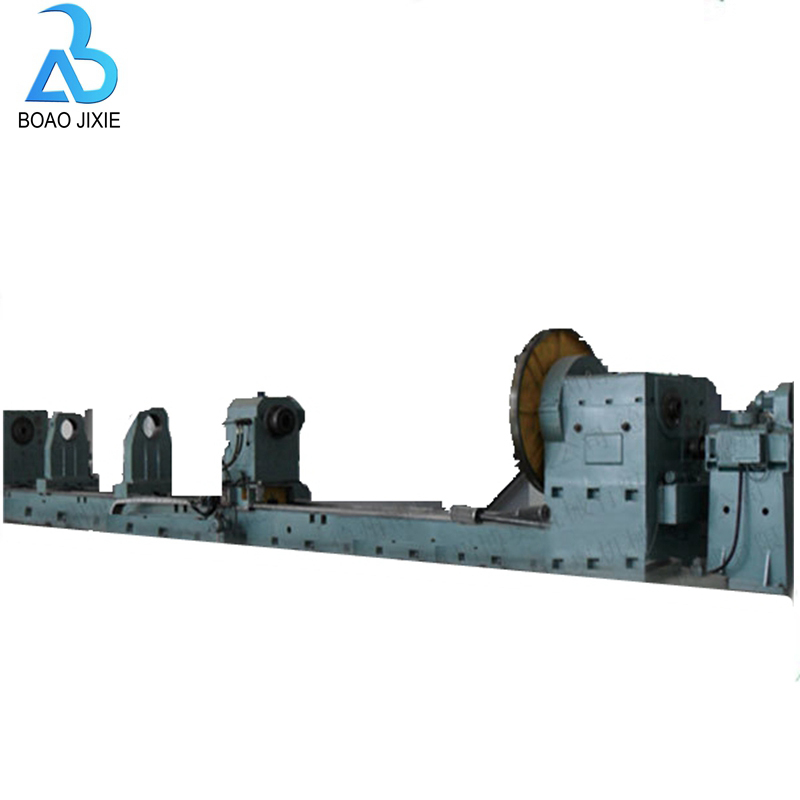

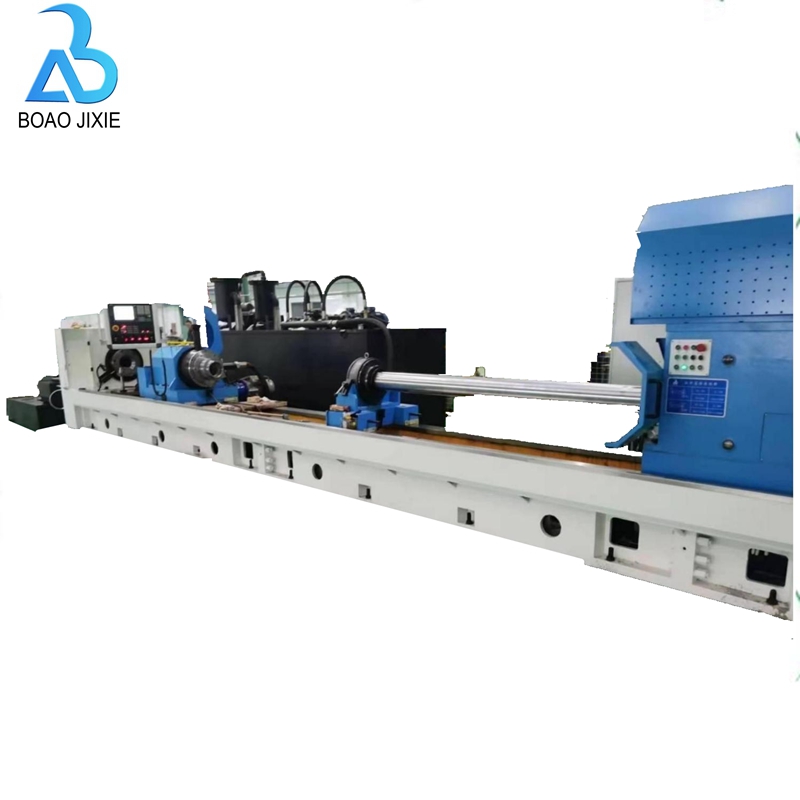

This machine tool is a modified product based on the original deep hole boring machine. In addition to all the functions of the original deep hole boring machine, it also has the function of CNC turning the outer circle. This machine tool is a special equipment for processing cylindrical deep hole workpieces. The machine tool itself has strong rigidity, good precision, wide range of spindle speed, and the feeding system is driven by high-power AC servo motor, which can meet the needs of various deep hole processing processes. The oil feeder adopts the main shaft structure, and the fastening of the oil feeder and the clamping workpiece adopts the worm gear mechanical device. The machine tool adopts push boring in the way of boring and eliminating, and adopts the processing method of workpiece rotation and tool feeding when boring. In the way of chip removal, oil is fed into the end of the boring bar to remove chips forward, and it can also be processed by rolling. It is suitable for mass production and small batch production in production. The instrument display is safe and reliable.

| NO | Items | Description |

| 1 | Machine model series | T2280H |

| 2 | Boring diameter | Φ280-750mm |

| 4 | Boring depth | 1-12m |

| 5 | Fixture clamping range | Φ400-850mm |

| 6 | Machine spindle center height | 800mm |

| 7 | Headstock spindle speed | 1-134 r/m , 2 gears, stepless |

| 8 | Spindle hole diameter | Φ130mm |

| 9 | Spindle front taper hole diameter | 140 # |

| 10 | Boring bar box spindle hole diameter | Φ120 |

| 11 | X axis motor | 23N·M (AC servo) |

| 12 | Z axis motor | 36N·M (AC servo) |

| 13 | Carriage of headstock fast moving speed | 2m/min |

| 14 | Feeding speed range | 5-1000mm/min, stepless |

| 15 | Main motor motor | 45 kw |

| 16 | Hydraulic pump motor power | 1.5KW |

| 17 | Carriage motor power | 3KW |

| 18 | Feed motor power | 7.5kw |

| 19 | Coolant pump motor | N=5.5kw ( 3 groups) |

| 20 | Coolant system rated pressure | 2.5Mpa |

| 21 | Cooling system flow | 300、600、900 L/min |

| 22 | Max loading weight on machine | 20T |

Important Machine Parts