T2150 Special Deephole Drilling Boring Machine for Energy Wind Spindle Motor

Machine Character

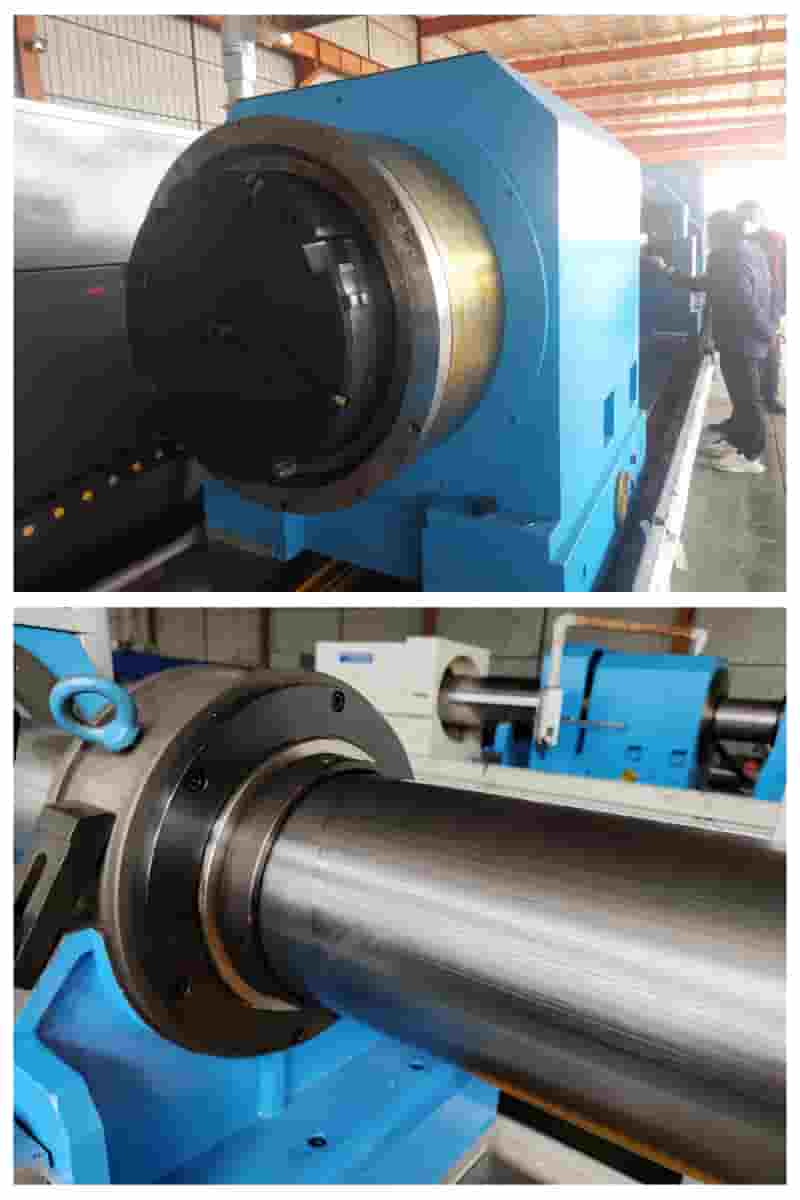

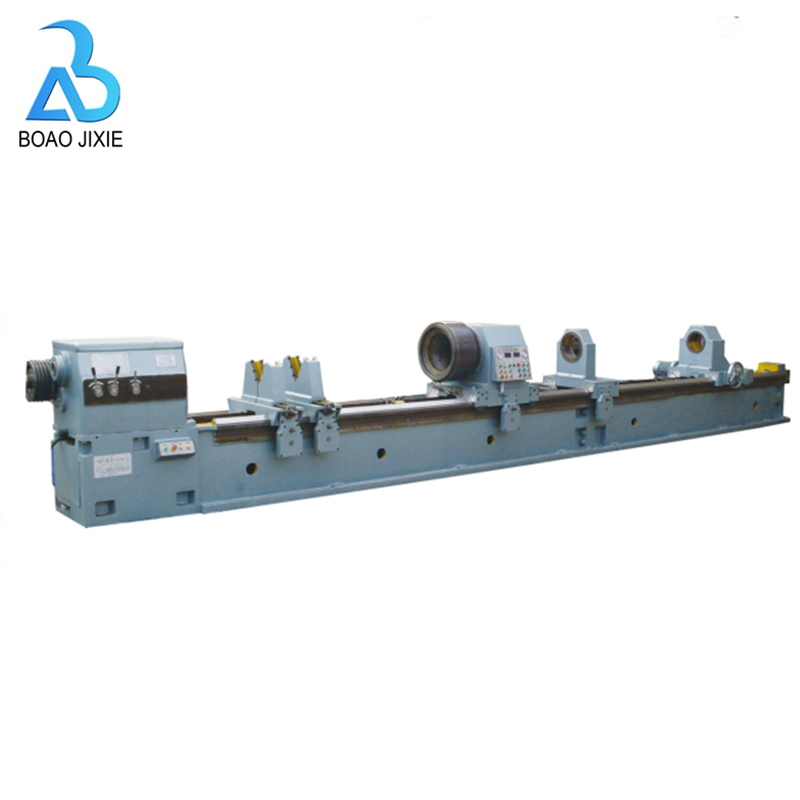

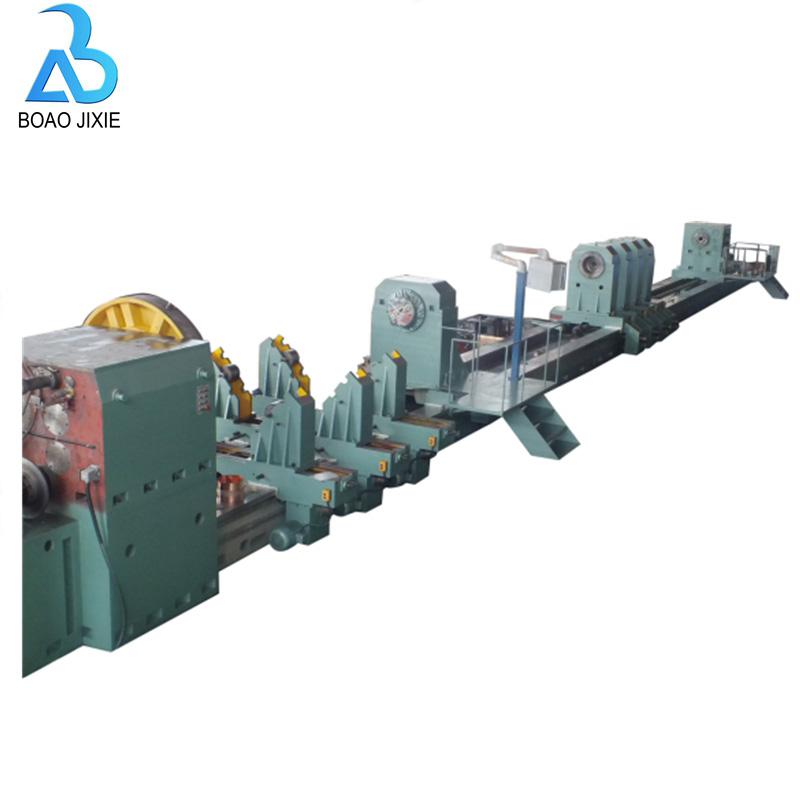

T2150 deep hole drilling and boring machine is a heavy-duty series deep hole machine tool developed by our company according to the processing characteristics of current wind power spindle workpieces and market needs. The machine tool itself has strong rigidity and maintains good precision. The spindle adopts three-speed stepless speed regulation (high, empty, low), and the speed range is wide. The feed system is driven by a high-power AC servo motor, which can meet the needs of various deep hole processing processes. . The oiler is used to tighten the workpiece with a mechanical device, which is safe and reliable. The machine tool can complete the drilling, boring, expanding and rolling processing of large-diameter heavy-duty deep-hole parts. During processing, the workpiece rotates at a low speed, and the tool rotates and feeds at a high speed. When drilling, adopt the technological method of chip removal in BTA; when boring, adopt the technological method of supplying cutting fluid in the boring bar and discharging cutting fluid and iron filings forward (the head end); according to the processing needs, the machine tool is equipped with a drill Rod box, tool can be rotated and fed. The machine tool mainly includes bed, bed head box, drill pipe box, oil feeder, feed system, workpiece center frame, workpiece bracket, boring bar support, feed carriage, cooling system (with chip removal device), hydraulic system . This machine tool can flexibly choose the processing method according to the actual needs, and has a wide range of applications.

| NO | Items | Description |

| 1 | Machine model series | T2150 |

| 2 | Drilling diameter rang | Φ30-120mm |

| 3 | Boring diameter rang | Φ220-500mm |

| 4 | Boring depth | 1-12m |

| 5 | Fixture clamping range | Φ1600mm |

| 6 | Machine spindle center height | 900mm |

| 7 | Headstock spindle speed | 1-225 r/m , 3 gears, stepless |

| 8 | Spindle hole diameter | Φ130mm |

| 9 | Spindle front taper hole diameter | 140 # |

| 10 | Boring bar box spindle hole diameter | Φ120 |

| 11 | Boring bar box spindle front taper hole | 140#, 1:20 |

| 12 | Boring bar box spindle speed | 20-400 rpm, 6 leavels |

| 13 | Pallet rapid moving speed | 2m/min |

| 14 | Feeding speed range | 5-1000mm/min, stepless |

| 15 | Main motor motor | 45 kw |

| 16 | Boring bar motor | 22KW |

| 17 | Feed motor power | 1.5kw |

| 18 | Feeding carriage rapid motor power | 5.5KW |

| 19 | Coolant pump motor | N=5.5kw ( 3 groups) |

| 20 | Coolant system rated pressure | 2.5Mpa |

| 21 | Cooling system flow | 100、200、500 L/min |

| 22 | Coolant system rated rated pressure | 6.3 Mpa |

| 23 | Max loading of axis force | 6.3 Kn |

| 24 | Max oiler fixing force for workpiece | 20KN |

| 25 | Max loading weight on machine | 20T |

| 26 | Control system | Siemens 808 or KND |

Important Machine Parts