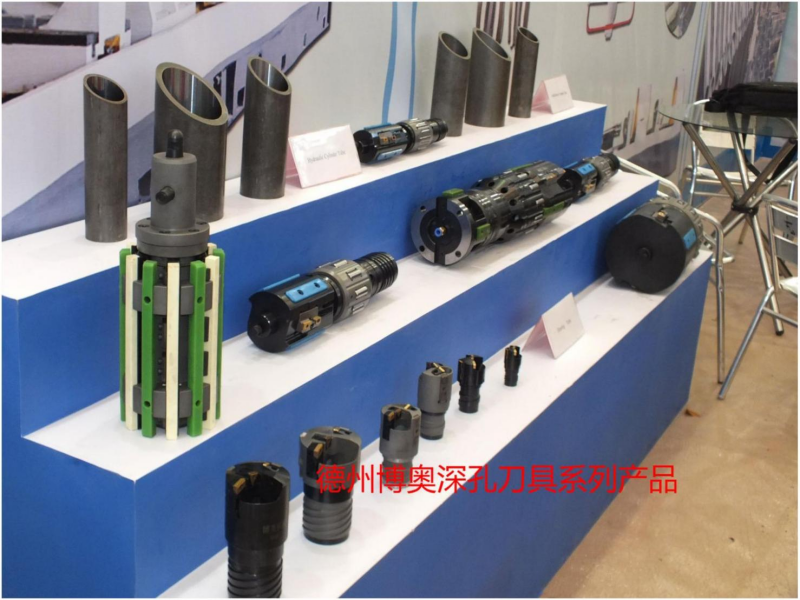

Pneumatic Boring Tools for deephole boring machines

Pneumatic Boring Tools

Normal items :

| Boring range | Boring bar | Boring range | Boring bar | Boring range | Boring bar |

| Φ35-Φ37 | Φ30 | Φ38-Φ45 | Φ35 | Φ46-Φ56 | Φ43 |

| Φ57-Φ60 | Φ51 | Φ61-Φ69 | Φ56 | Φ70-Φ89 | Φ65 |

| Φ90-Φ120 | Φ80 | Φ121-Φ139 | Φ100 | Φ140-Φ169 | Φ130 |

| Φ170-Φ230 | Φ160 | Φ231-Φ400 | Φ220 |

PneumaticSRBTools

Operation : The tool moves forward for skiving , and backward for roller burnishing .With 2 groups of insert on the top end, it can achieve high sizing precision and good shape control :With 4 groups of guide pad, it can achieve the excellent guidance and balanced skiving , also prevent from scraping on the hole surface : the inserts are retracted by pneumatic control .

Features

To be used for machining various tubes including cold drawn seamless steel tube , welded cold drawn tube , hot roller steel tube and cast steel tube . Easily and rapidly adjust the sizes of inserts , guide pads and rollers . At the completion of processing , adjust cartridge by pneumatic control to prevent from damage on the hole surface . Adopting the design with high efficiency , combining fine skiving and roller burnishing , and achieving one - off machining ,it provides the tool with along life and has a high efficiency of 20 times traditional honing machine and 510times ordinary boring machine. At the completion of processing .the surface hardness increases about 30%,the precision is up to IT8.Surface finish is up to Ra0.05-0.2