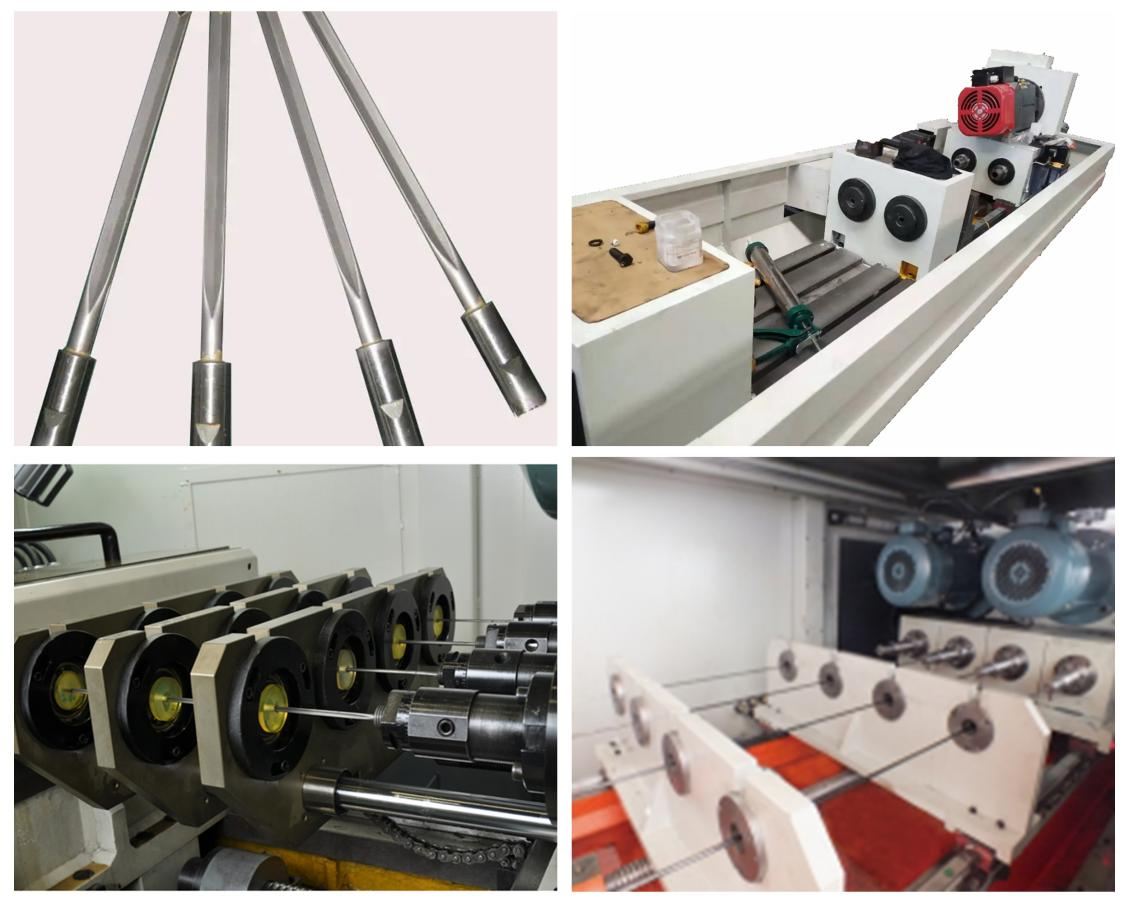

High Performance Deep Hole Drilling BTA Metal Drilling Tool

Pneumatic Boring Tools

The BTA (Boring & Trepanning Association) System was developed largely by an international group of tool manufacturers. This system was one of the first successful systems of internal chip removal tools, and includes a drilling, a boring, and a trepanning head and is considered the best system in hole making work that utilizes high pressure coolant tools.

In the BTA system hole making process, fluid under pressure flows to the setting edge over the O.D. of the boring bar and head, and exhausts with the chips through the I. D. of the boring bar. Clean filtered fluid flows constantly over the outside of the head, thus lubricating the guide pads which act as a burnishing tool to produce a smoother finish, and capable of high rate of feed. Hole depth is obtainable as much as 150 diameters or deeper.

Feature

1. High quality and competitive price

2. Delivery goods in time

This BTA drill head adopt imported indexable coating blade, it has the advantage of high efficiency, change blade easily, long service life , low using cost. And it can drill on carbon steel, high strength alloy steel ,stainless steel and so on.precision of hole diameter IT9-11. Surface roughness:Ra6.3-12.5