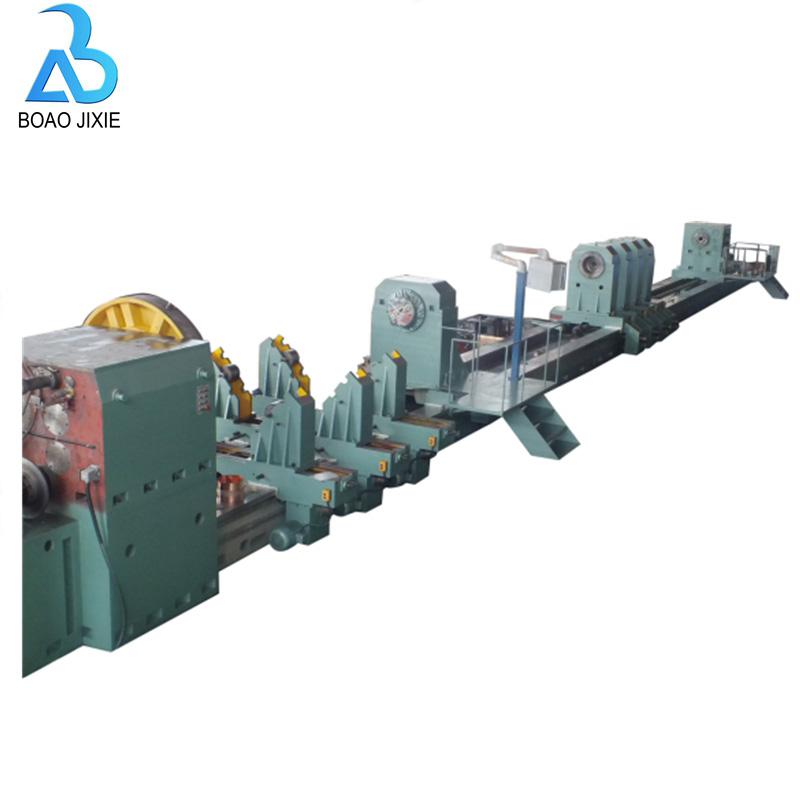

Good quality heavy duty deep hole boring machines

Product Description

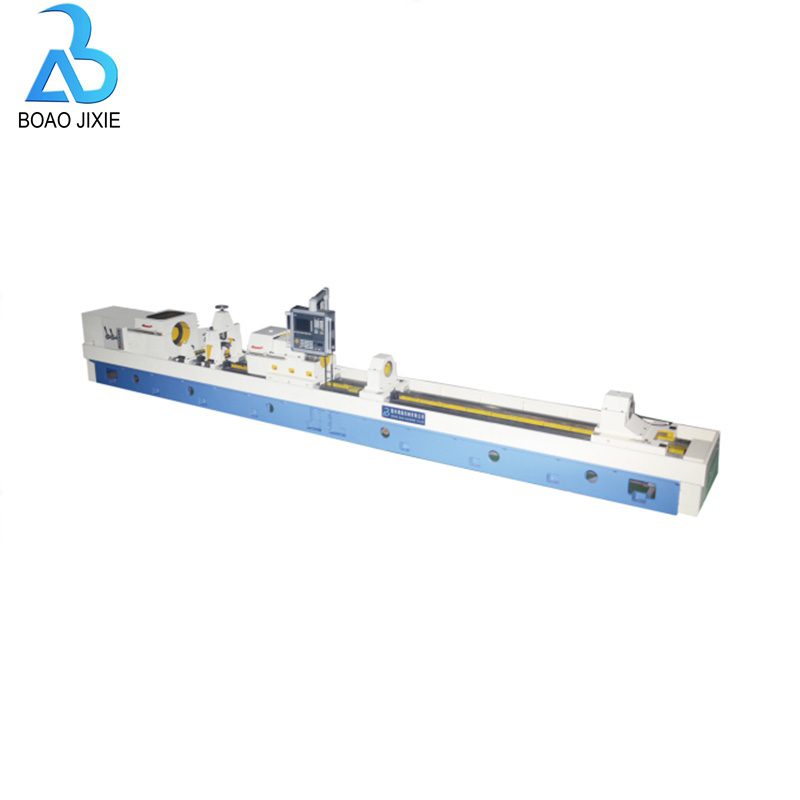

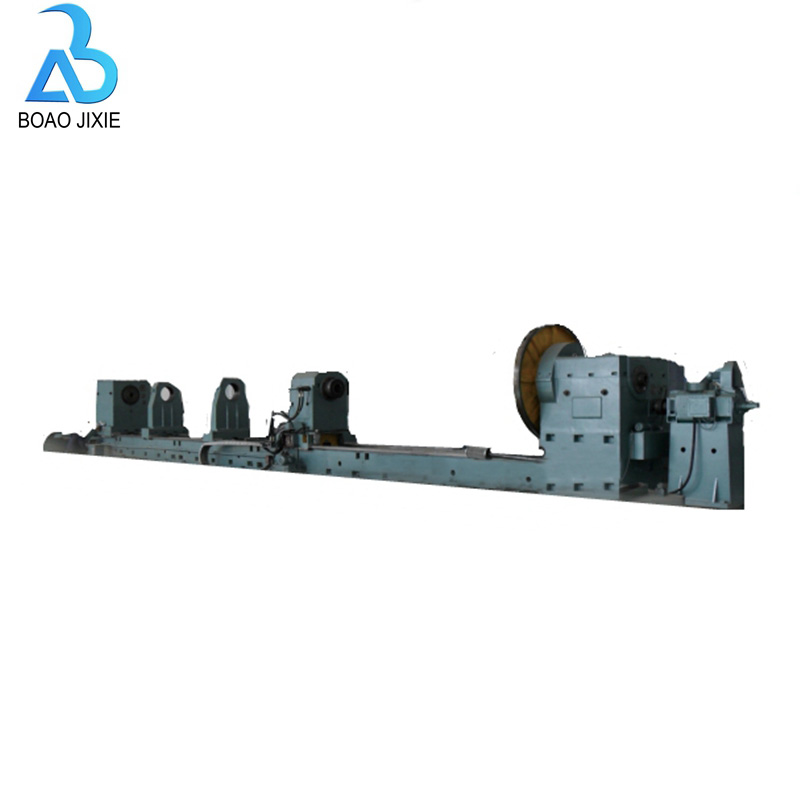

T22100 heavy duty deep hole boring machine is specially for processing of large and heavy duty cylindrical workpiece. The machine body has the strong rigidity and good precision retaining ability. The spindle adopts three shifts with stepless speed regulation(high, neutral, low) in a wide range. Feed system is driven by large power AC servo motor, which meets the different processing demands. The oil feeder clamps the workpiece by mechanical device, which is very safe and reliable. The machine can perform boring of heavy duty components in a large diameter. When boring, the cutting liquid is supplied to cutting area through boring bar, and the chip is discharged forward to headstock end.

When trepanning, the external chip removal mode is used, and the special tool, tool bar and clamping device should be equipped.The machine consists of bed body, headstock, oil feeder, feed system, steady rest, workpiece support, boring bar support, feed carriage, cooling system, hydraulic system and electric system, etc.

Specifications

|

NO |

Items |

Description |

|

1 |

Models |

T2280 |

|

2 |

Boring diameter range |

Φ320-Φ1000mm |

|

3 |

Boring depth range |

1000-15000mm |

|

4 |

Workpiece clamping diameter range |

500-1350mm |

|

5 |

Guideway width |

1250mm |

|

6 |

Machine spindle center height |

1000mm |

|

7 |

Rotation speed range of headstock spindle |

3-120r/min |

|

8 |

Spindle hole diameter |

Φ130mm |

|

9 |

Spindle Front taper hole diameter |

140# |

|

10 |

Headstock motor power |

55KW DC motor |

|

11 |

Feeding speed range |

0.5-450mm/min ( stepless ) |

|

12 |

Feeding carriage rapid speed |

2m/min |

|

13 |

Feed motor power |

36N.M |

|

14 |

Feed carriage rapid motor power |

7.5kw |

|

15 |

Hydraulic pump motor power |

N=1.5KW |

|

16 |

Rated work pressure of hydraulic system |

6.3Mpa |

|

17 |

Cooling pump motor power |

N=7.5KW(3 groups ) |

|

18 |

Rated work pressure of cooling system |

2.5Mpa |

|

19 |

Cooling system flow |

100、400、700L/min |

|

20 |

CNC control system |

Siemens 828 |