Good heavy duty deep hole boring machines with drilling tools

Product Description

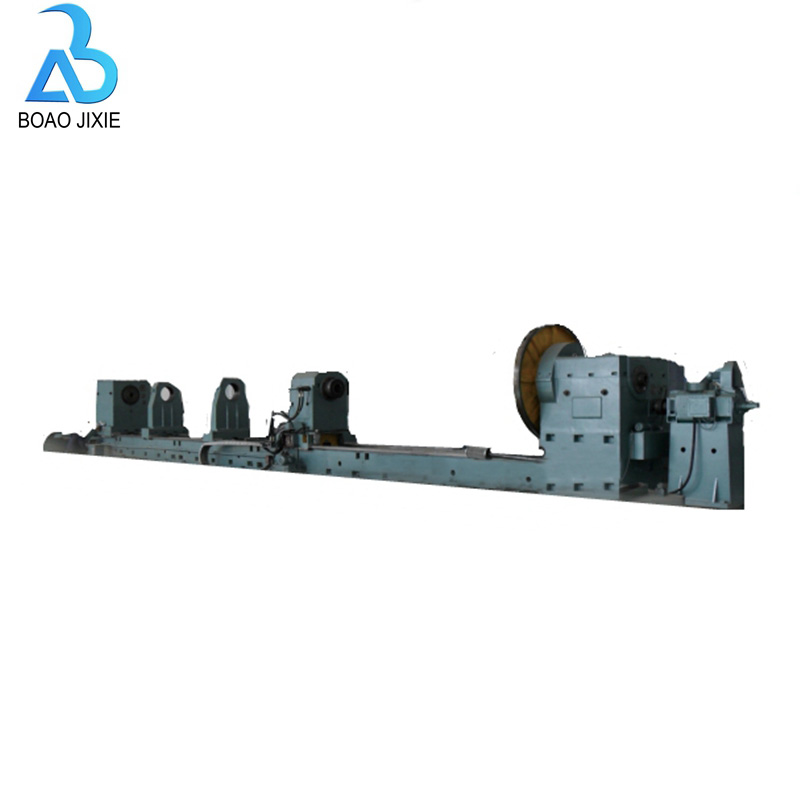

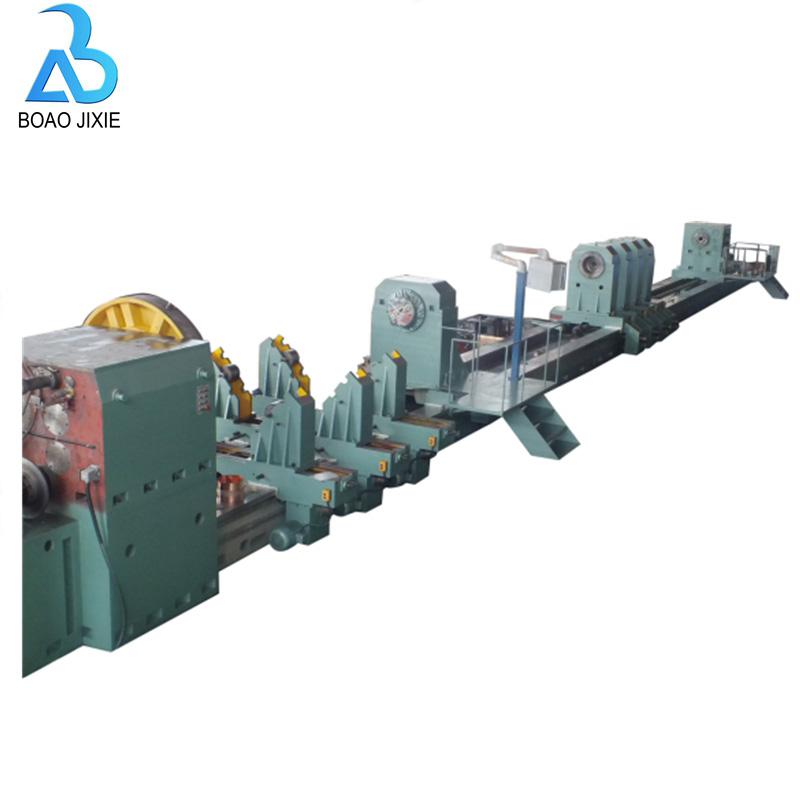

T2180 machine is mainly for processing of heavy duty cylindrical parts, such as drilling, boring, expanding, roller burnishing and trepanning, etc. The workpiece is kept slowly rotating, the tool is rapidly rotary while feeding. Besides machining through-hole, it can also process step hole and blind hole. This machine is used in a wide range, the process type can be chosen based on the actual demand.

When drilling, the machine adopts BTA internal chip removal type, the oil feeder supplies the cutting liquid to remove the chips out of the end of drill bar. When push-boring, the cutting liquid reaches cutting area through small hole of oil feeder or big hole at the end of boring bar.

The chip is flushed out of headstock end. When trepanning, the special tool, tool bar and clamping device should be equipped, the chip is discharged by the external removal type.

This machine is assembled with drill box, which achieves double rotation of workpiece and tool, the single action is also available based on the actual demand. When the workpiece needs a lower rotary speed, the process efficiency and quality can be assured.

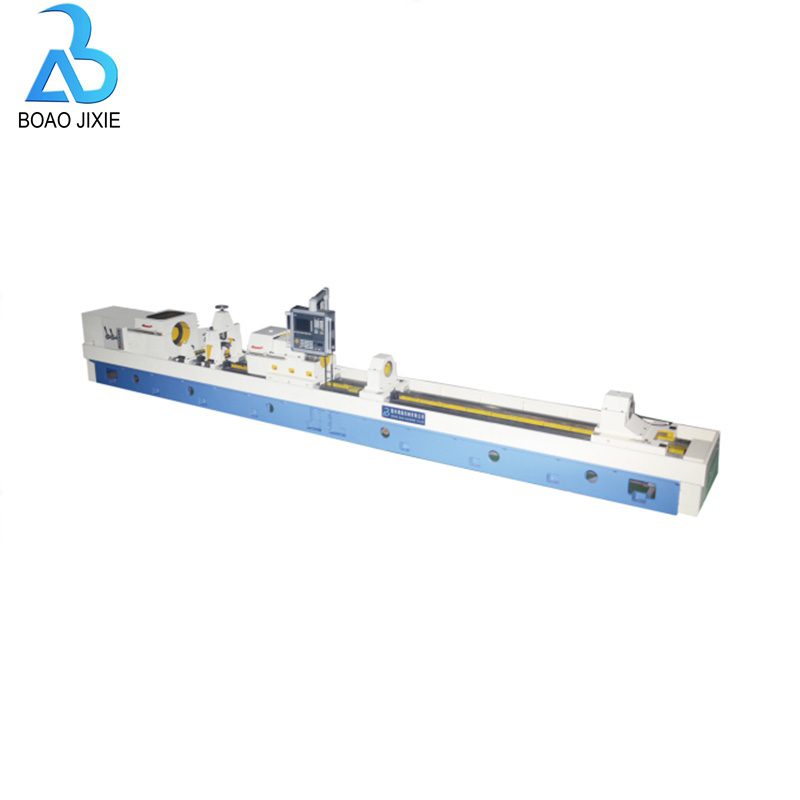

The headstock adopts heavy duty four-jaw chuck to lock the workpiece, the steady rest is for supporting and the oil feeder is for clamping by hydraulic pressure. The oil feeder adopts the principal axis structure which improves the load-capacity and rotation accuracy. The bed body has an excellent rigidity, good wear-resistance and high precision retaining ability. The tool feeding adopts AC servo motor to realize stepless speed regulation. The headstock uses DC motor with stepless speed regulation. The drill box is driven by large power motor, with speed regulating by gear shift.

The hydraulic system has an accurate control when clamping and fixing the workpiece, which has a high stability and precision. All the operation parameters are shown by meter display, the workpiece clamping and the operation is very safe, rapid and stable. The machine adopts PLC control with human-machine interface, it is easy to be operated.

Specifications

|

NO |

Items |

Description |

|

|

1 |

Models |

T2280 |

T2180 |

|

2 |

Drilling diameter range |

|

Φ60mm-Φ150mm |

|

3 |

Max boring diameter range |

Φ800mm |

Φ800mm |

|

4 |

Boring depth range |

1000-15000mm |

1000-15000mm |

|

5 |

Workpiece clamping diameter range |

320-1250mm |

320-1250mm |

|

6 |

Machine spindle center height |

1000mm |

1000mm |

|

7 |

Rotation speed range of headstock spindle |

3-120r/min |

3-120r/min |

|

8 |

Spindle hole diameter |

1-225r/min |

1-225r/min |

|

9 |

Spindle Front taper hole diameter |

Φ130mm |

Φ130mm |

|

10 |

Headstock motor power |

140# |

140# |

|

11 |

Drill box motor power |

|

30KW |

|

12 |

Drill box spindle hole diameter |

|

130mm |

|

13 |

The front taper hole dia. of drill box |

|

Φ85mm(1:20) |

|

14 |

Drill box speed range |

|

16-270r/min |

|

15 |

Feeding speed range |

5-2000mm/min ( stepless ) |

5-2000mm/min ( stepless ) |

|

16 |

Feeding carriage rapid speed |

2m/min |

2m/min |

|

17 |

Feed motor power |

11KW |

11KW |

|

18 |

Feed carriage rapid motor power |

36N.M |

36N.M |

|

19 |

Hydraulic pump motor power |

N=1.5KW |

N=1.5KW |

|

20 |

Rated work pressure of hydraulic system |

6.3Mpa |

6.3Mpa |

|

21 |

Cooling pump motor power |

N=7.5KW(2 groups )5.5KW(1group) |

N=7.5KW(2 groups )5.5KW(1group) |

|

22 |

Rated work pressure of cooling system |

2.5Mpa |

2.5Mpa |

|

23 |

Cooling system flow |

300、600、900L/min |

300、600、900L/min |

|

24 |

CNC control system |

Siemens 808orKND |

Siemens 808orKND |