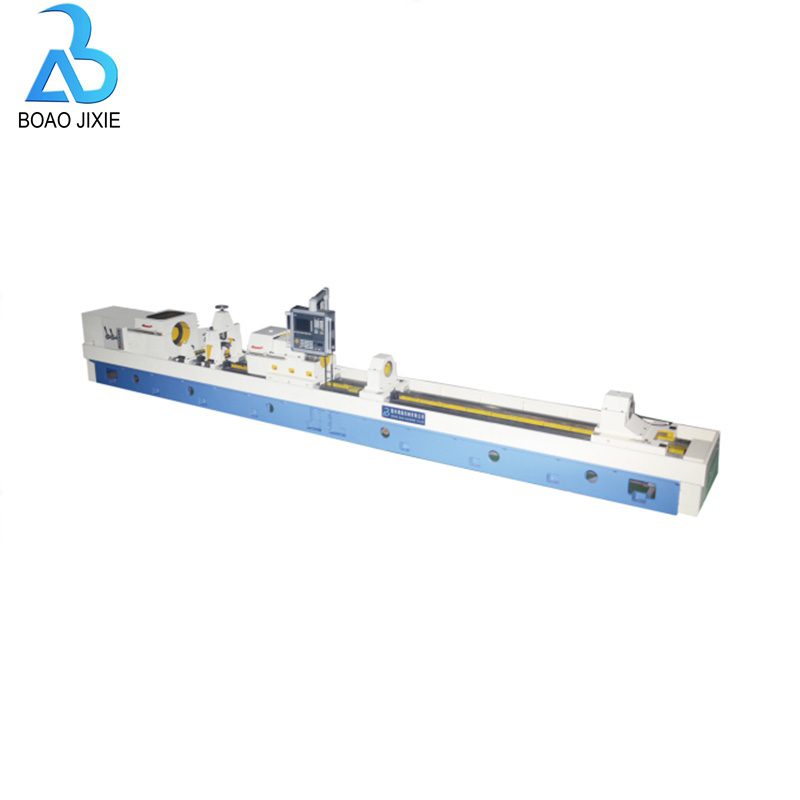

China CNC deephole drilling and boring machines company

Product Description

This machine is specially designed for deep hole processing of cylindrical workpiece, it can perform different processing, such as drilling, boring, expanding and roller burnishing, etc. Besides machining through-hole, it can also process step hole and blind hole.

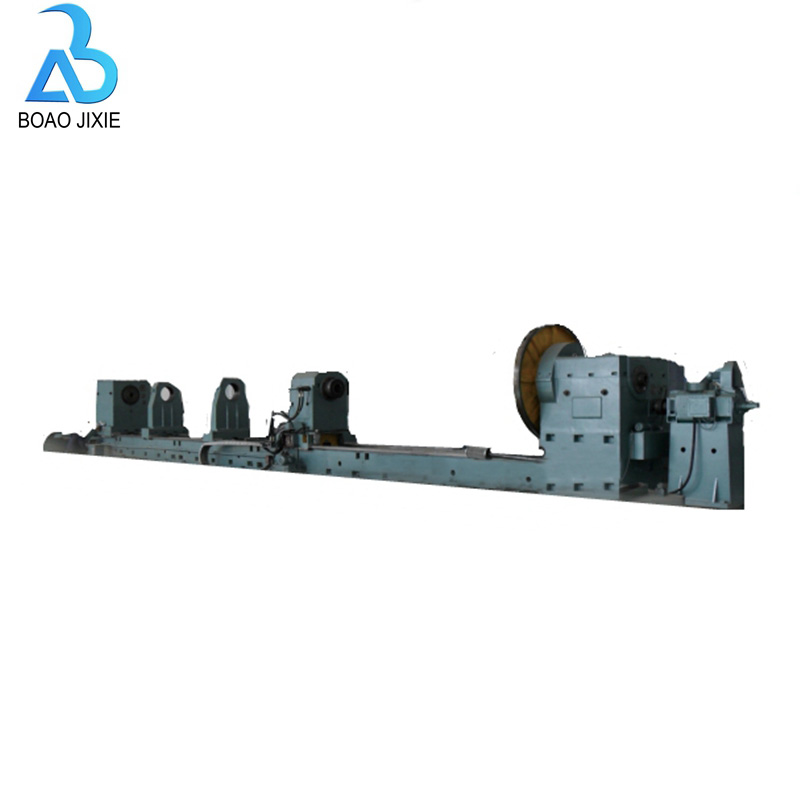

The process adopts the mode of workpiece rotating and tools feeding, if necessary the tool can be also rotary. With the workpiece rotating and the tool feeding, the cutting fluid reaches the cutting area by oil supply device or through boring bar end, the chip removal adopts BTA type. When boring, the cutting fluid pushes chips forward out of headstock end.

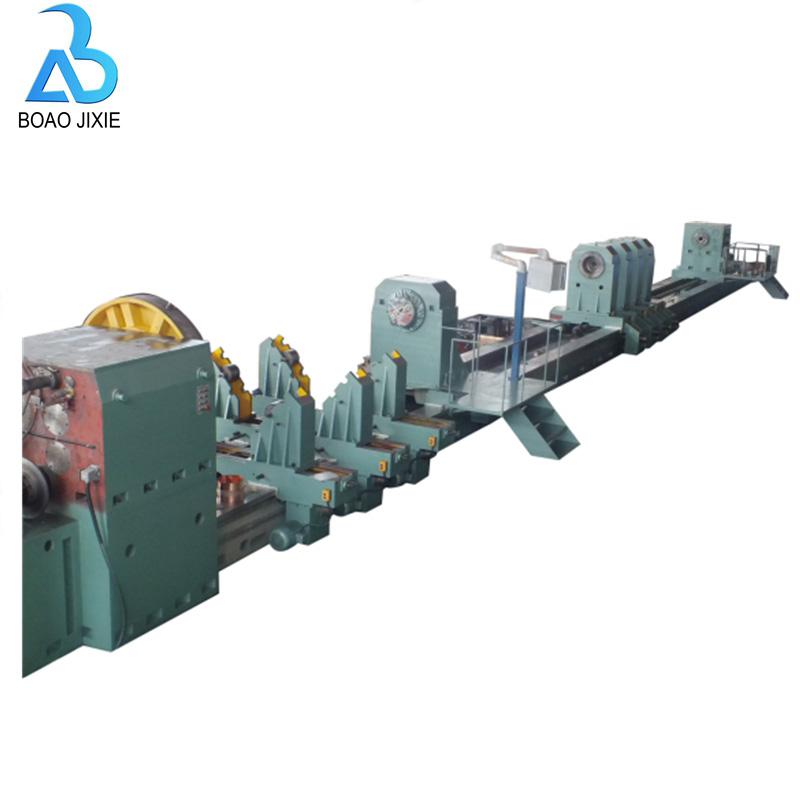

To meet the different processing demand, the machine can be equipped with drilling box, achieving double rotation of workpiece and tools, and the single action is also available. Under the conditions of lower speed rotation of the workpiece, the processing efficiency and quality can be assured.

This machine has a wide application according to different processing demand.

The machine consists of bed body, headstock, drill box(optional), chuck body, carriage feed system, oil feeder, cooling system, chips removal device, steady rest, hydraulic system, boring bar support, motor device and electrical control system, etc.

Specifications

|

NO |

Items |

Description |

|

|

1 |

Machine model series |

T2235 |

T2135 |

|

2 |

Drilling diameter rang |

/ |

Φ30-80mm |

|

3 |

Boring diameter rang |

Φ60-350mm |

Φ60-350mm |

|

4 |

Boring depth |

1-12m |

1-12m |

|

5 |

Fixture clamping range |

Φ120-450mm |

Φ120-450mm |

|

6 |

Machine spindle center height |

450mm |

450mm |

|

7 |

Headstock spindle speed |

61-1000 r/m , 12 levels |

61-1000 r/m, 12 levels |

|

8 |

Spindle hole diameter |

Φ75mm |

Φ75mm |

|

9 |

Spindle front taper hole diameter |

Φ85mm (1:20) |

Φ85mm (1:20) |

|

10 |

Main motor motor |

30 kw |

30 kw |

|

11 |

Feeding speed range |

5-2000mm/min stepless |

5-2000mm/min stepless |

|

12 |

Feeding carriage rapid speed |

2m/min |

2m/min |

|

13 |

Feed motor power |

36N.M |

36N.M |

|

14 |

Feeding carriage rapid motor power |

3KW |

3KW |

|

15 |

Max. axial force of oil feeder |

6.3KN |

6.3KN |

|

16 |

Max.clamping force of oil feeder |

20KN |

20KN |

|

17 |

Hydraulic pump motor power |

1.5KW |

1.5KW |

|

18 |

Hydraulic system rated working pressure |

6.3 Mpa |

6.3 Mpa |

|

19 |

Coolant pump motor |

N=5.5kw ( 4 groups) |

N=5.5kw ( 4 groups) |

|

20 |

Coolant system rated pressure |

2.5Mpa |

2.5Mpa |

|

21 |

Cooling system flow |

100、200、300, 400 L/min |

100、200、300, 400 L/min |

|

22 |

Control system |

Siemens 808 or KND |

Siemens 808 or KND |