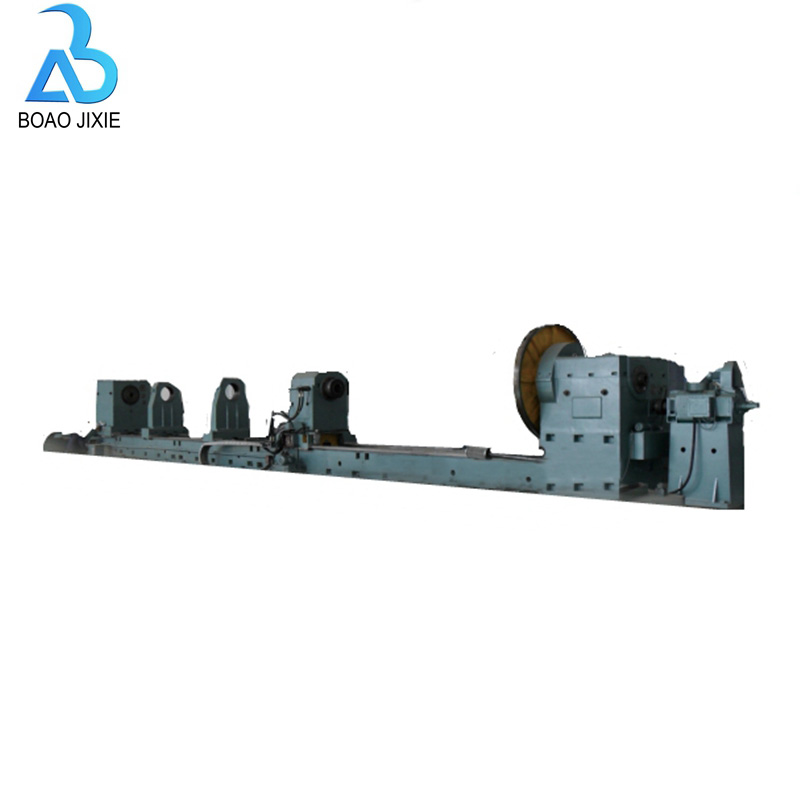

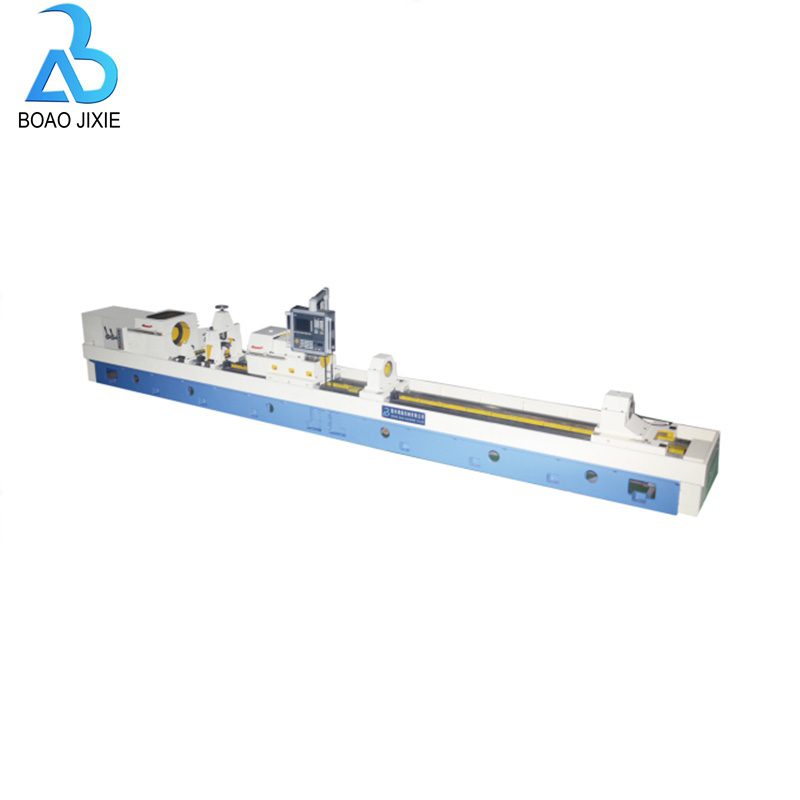

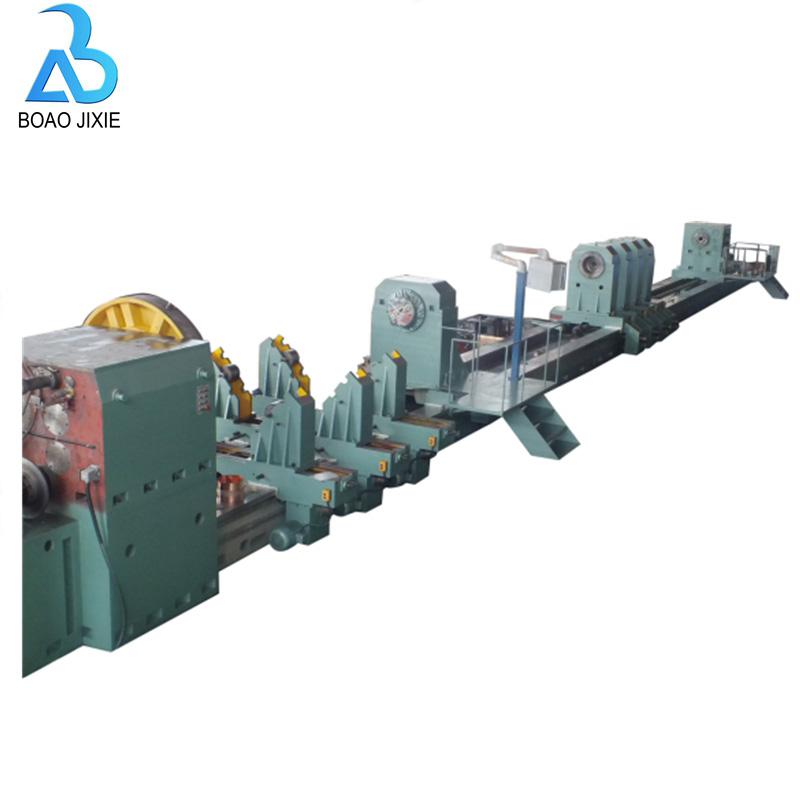

China deep hole drilling and boring machines supplier

Product Description

T21xx series machine is specially designed for deep hole processing of cylindrical workpiece, it is applicable to the process of drilling and boring. When drilling the machine adopts internal chip-removal (BTA type), the cutting oil is supplied by oil feeder to cutting area, the chip is discharged through the inner hole of drilling bar and is collected into the chip container located in the back part of the machine. The machine is equipped with high efficient compound tool, the skiving roller burnishing tool can be expanded and retracted automatically, it can achieve high efficient processing for oil cylinder production. Germany WENAROLL tool can be chosen, and the customer can also use the tool manufactured by our company.

Specifications

|

NO |

Items |

Description |

|

|

1 |

Machine model series |

TK2110G |

TK2110G/1 |

|

2 |

Drilling diameter rang |

Φ30-60mm |

Φ30-60mm |

|

3 |

Boring diameter rang |

Φ40-125mm |

Φ40-125mm |

|

4 |

Boring depth |

0.5-8m |

0.5-8m |

|

5 |

Fixture clamping range |

Φ40-200mm |

Φ40-200mm |

|

6 |

Machine spindle center height |

300mm |

300mm |

|

7 |

Headstock spindle speed |

200-1200 r/m |

200-1200 r/m |

|

8 |

Spindle hole diameter |

Φ75mm |

Φ75mm |

|

9 |

Spindle front taper hole diameter |

Φ85mm (1:20) |

Φ85mm (1:20) |

|

10 |

Headstock motor |

15 kw , frequency |

15 kw , frequency motor |

|

11 |

Drill box motor |

/ |

15 kw |

|

12 |

Drill box spindle hole diameter |

/ |

Φ75mm |

|

13 |

The front taper hole of drill box |

/ |

Φ85mm (1:20) |

|

14 |

Drill box speed |

/ |

40-500r/min, stepless |

|

15 |

Feeding speed range |

5-1500mm/min |

5-1500mm/min |

|

16 |

Feeding carriage rapid speed |

3.2m/min |

3.2m/min |

|

17 |

Feed motor power |

5.5KW |

5.5KW |

|

18 |

Feeding carriage rapid motor power |

3KW |

3KW |

|

19 |

Hydraulic pump motor power |

N=1.5KW |

N=1.5KW |

|

20 |

Hydraulic system rated working pressure |

6.3 Mpa |

6.3 Mpa |

|

21 |

Coolant pump motor |

N=5.5kw ( 3 groups) |

N=5.5kw ( 3 groups) |

|

22 |

Coolant system rated pressure |

2.5Mpa |

2.5Mpa |

|

23 |

Cooling system flow |

100、200、300L/min |

100、200、300L/min |

|

24 |

Control system |

Siemens 808 or KND |

Siemens 808 or KND |

|

25 |

Power supply |

380V, 50HZ, 3phase |

380V, 50HZ, 3phase |

|

NO |

Items |

Description |

|

|

1 |

Machine model series |

TK2220G |

TK22120G/1 |

|

2 |

Drilling diameter rang |

Φ30-80mm |

Φ30-80mm |

|

3 |

Boring diameter rang |

Φ40-200mm |

Φ40-200mm |

|

4 |

Boring depth |

0.5-12m |

0.5-12m |

|

5 |

Fixture clamping range |

Φ60-300mm |

Φ60-300mm |

|

6 |

Machine spindle center height |

350mm |

350mm |

|

7 |

Headstock spindle speed |

61-1000 r/m |

61-1000 r/m |

|

8 |

Spindle hole diameter |

Φ75mm |

Φ75mm |

|

9 |

Spindle front taper hole diameter |

Φ85mm (1:20) |

Φ85mm (1:20) |

|

10 |

Headstock motor |

30 kw , frequency |

30 kw , frequency |

|

11 |

Drill box motor |

/ |

22 kw |

|

12 |

Drill box spindle hole diameter |

/ |

Φ75mm |

|

13 |

The front taper hole of drill box |

/ |

Φ85mm (1:20) |

|

14 |

Drill box speed |

/ |

40-500r/min, stepless |

|

15 |

Feeding speed range |

5-3200mm/min |

5-3200mm/min |

|

16 |

Feeding carriage rapid speed |

3.2m/min |

3.2m/min |

|

17 |

Feed motor power |

5.5KW |

5.5KW |

|

18 |

Feeding carriage rapid motor power |

3KW |

3KW |

|

19 |

Hydraulic pump motor power |

N=1.5KW |

N=1.5KW |

|

20 |

Hydraulic system rated working pressure |

6.3 Mpa |

6.3 Mpa |

|

21 |

Coolant pump motor |

N=5.5kw ( 4 groups) |

N=5.5kw ( 4 groups) |

|

22 |

Coolant system rated pressure |

2.5Mpa |

2.5Mpa |

|

23 |

Cooling system flow |

100、200、300,400L/min |

100、200、300,400L/min |

|

24 |

Control system |

Siemens 808 or KND |

Siemens 808 or KND |

|

25 |

Power supply |

380V, 50HZ, 3phase |

380V, 50HZ, 3phase |